Gernal

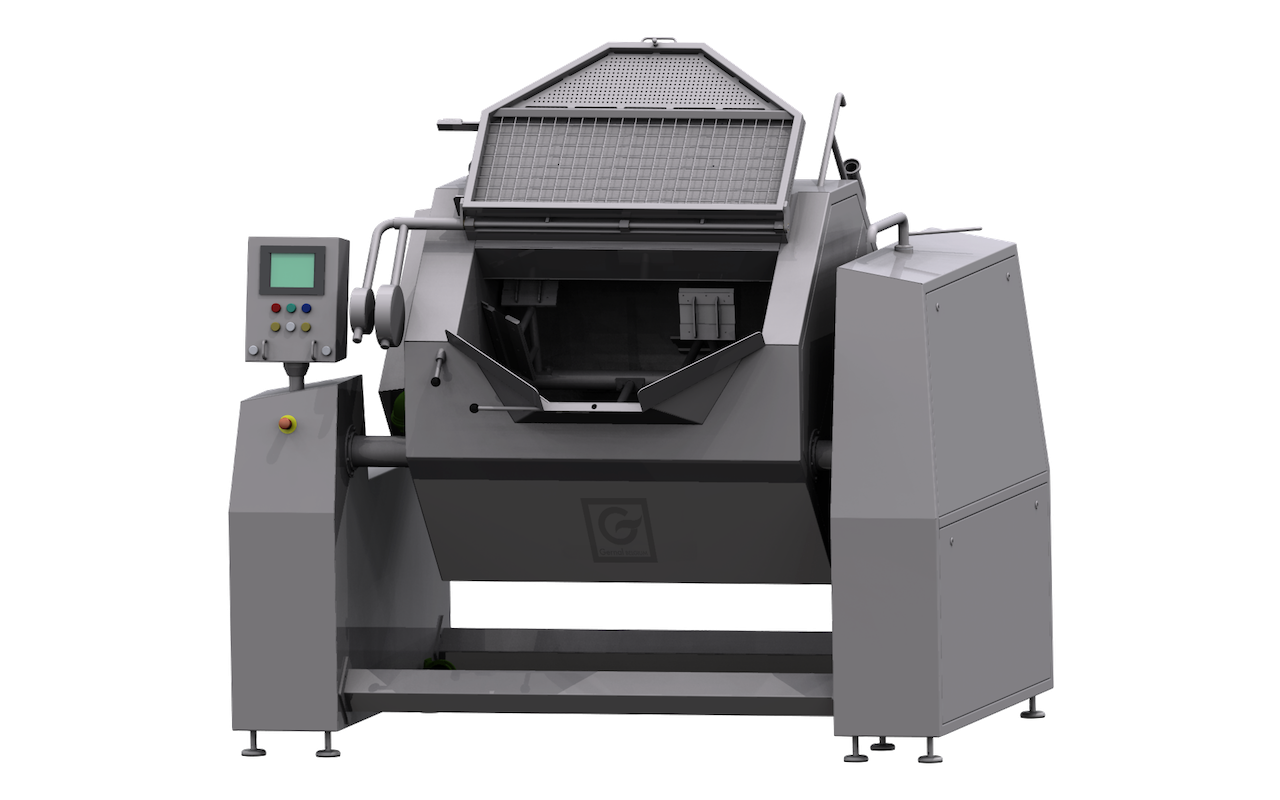

Gernal Model MBK 800 Tilting Searing Boiler Kettle

Gernal Model MBK 800 Tilting Searing Boiler Kettle

The Gernal Model MBK 800 Tilting Searing Boiler Kettle is the ideal solution for preparing dishes faster and more efficiently with a capacity of 132 Gallons (800 Liters). The Gernal Model MBK 800 Tilting Searing Boiler Kettle is very versatile and perfect for sequential cooking. Operating the Gernal Model MBK 800 Tilting Searing Boiler Kettle is easy thanks to a large and multifunctional LCD display. Choose at a glance between multiple recipes. With this machine your guaranteed consistent quality and shorter changeover times. The operator of the Gernal Model MBK 800 Tilting Searing Boiler Kettle can determine the production steps and have them appear on the touchscreen. You can also fine-tune all cooking and cycle parameters yourself, depending on your product, for the perfect cooking time.

✔ Perfect stir-frying for the most delicious dishes in a single machine

✔ Wok your vegetables briefly and al dente without sticking

✔Create tasty stews with our slow-cooking technology

We can make modifications to size, heating elements and other features. Our Gernal machines including the Gernal Model MBK 800 Tilting Searing Boiler Kettle can be equipped with a large range of options. Customers can also request entirely new designs. Our engineering department can develop a new machine for your complex and specific problem.

RAM Manufacturing Equipment located in Corona, California, offers training, installation, service and parts for all the machines we sell. Including the Gernal Model MBK 800 Tilting Searing Boiler Kettle and many others. Call or visit us today for more information!

Call or Visit at:

951-734-8152

235 Benjamin Dr. Suite 102

Corona, CA 92879

Find this machine and many others at our alternative website link below:

https://ramaxwell.com/products/model-mbk-800-tilting-searing-boiler-kettle

Features

- ✔Performance and robustness for reliable production quality

- ✔ Fast Heat Up Cycle

- ✔ High-energy baking to preserve taste and texture

- ✔ Program your own recipes with the comfortable and intuitive touchscreen

- ✔ Optimized agitator for effective mixing of your product

- ✔ Short changeover times and ready for the next cycle

- ✔Large capacity: 800 Liters (211 Gallons)

- ✔ Hygienic design, optimally cleanable

- ✔ High-quality #304 stainless steel

- ✔ Use of traceable materials

- ✔ Stirrer with heat-resistant scrapers avoid burnt, unusable preparations

- ✔ Durable insulated fairing

- ✔ Energy Saving Lid

- ✔ Heat recovery via closed cooling water circuit

- ✔ Use of product residual heat in multi-step cooking

- ✔ Optimal heat transfer through maximum contact surface

- ✔ Drain valve for controlled and safe emptying of the boiler, with option to connect a pump unit

- ✔ Optimal reading height display, meters

- ✔ Optimal working height control buttons

Optional Features

- Water-saving flow meter (optional)

- available with a loader for standard trucks

- No overload for the operator, the boiler tilts hydraulically (option)

- heating/cooling in 2 zones in combination with a proportional steam valve for optimal temperature control of your product

- Cooling wall to prevent overcooking and to drain your products in a safe way

- An accurate weighing system for a perfect dosage of your ingredients

- Direct steam injection for shorter heat-up times

- High flow pneumatic full bore discharge

Specifications

| Model | MBK 800 |

|---|---|

| L" x W" x H" | 113.9" x 65.3" x 52.2" |

| Capacity | 132 Gallons (800 Liters) |

| Electrical | 400V / 3F + N + A |

| Kettle Plate Thickness | 8mm (0.314in) |

Couldn't load pickup availability

Materials

Materials

Dimensions

Dimensions

Shipping & Returns

Shipping & Returns

-

Industry's Best Customer Service

Call our friendly and knowledgeable team to make sure you're getting the right item for the job. Our team has decades of food processing experience and is looking forward to hearing from you! 951-734-8152 or email us at support@rameqpt.com

-

Fast Shipping

We stock many of our items at our main facility in Corona, CA. Other items are ship form our 14 Strategically located distribution centers nationwide and internationally. Equipment is usually made to order and lead times vary. Contact us today for current equipment lead times. 951-734-8152.