MHS Scheidetechnik

MHS Model IC 70-36 Horizontal Meat Slicer with Outfeed Conveyor

MHS Model IC 70-36 Horizontal Meat Slicer with Outfeed Conveyor

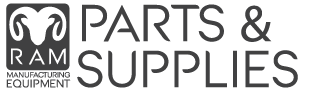

The MHS Model IC 70-36 Horizontal Meat Slicer with Outfeed Conveyor features all # 304 stainless steel construction. The removable parts are utilized to make slicing and portioning machines easy to clean, sanitize and maintain. The MHS Model IC 70-36 Horizontal Meat Slicer with Outfeed Conveyor offers options such as double blades, take-away conveyors and programmable slicing parameters to allow the machine to be configured to meet your specific needs. Contact RAM Manufacturing Equipment so we can educate you or your staff today on the capabilities of the different products and processes that our horizontal Meat Slicer and portioning machines can be used for as well as help you purchase the right model with the proper options to meet your specific needs.

We have sold the MHS Model IC 70-36 Horizontal Meat Slicer with Outfeed Conveyor to companies slicing beef products such as beef jerky, bacon, Korean BBQ meats, pet food and pet treats, salami and other hard deli meats, cheese steak, thin sliced Milanese, boneless ribeye and New York Strips.

The MHS Model IC 70-36 Horizontal Meat Slicer with Outfeed Conveyor is also used to slice bone-in porkchops and boneless pork products. As well as poultry such as chicken breast and thigh meat.

If you want to purchase one of the best horizontal slicers and portion control machines on the world market, contact us about our MHS Model IC 70-36 Horizontal Meat Slicer with Outfeed Conveyor. When you purchase a horizontal slicer from RAM Manufacturing Equipment, we will provide training on safety, maintenance, cleaning and how to operate the MHS Model IC 70-36 Horizontal Meat Slicer with Outfeed Conveyor.

RAM Manufacturing Equipment located in Corona, California, offers training, installation, service and parts for all the machines we sell. Including the MHS Model IC 70-36 Horizontal Meat Slicer with Outfeed Conveyor machine and many others. Call or visit us today for more information!

Call or Visit at:

951-734-8152

235 Benjamin Dr. Suite 102

Corona, CA 92879

Features

- Designed for heavy duty, the operation is reduced to a minimum. The machine can be operated

- Exact portioning thanks exact feed with servo-technology and anti-friction surface

- The operator keyboard is made of synthetic material with single removable buttons for fast and easy cleaning.

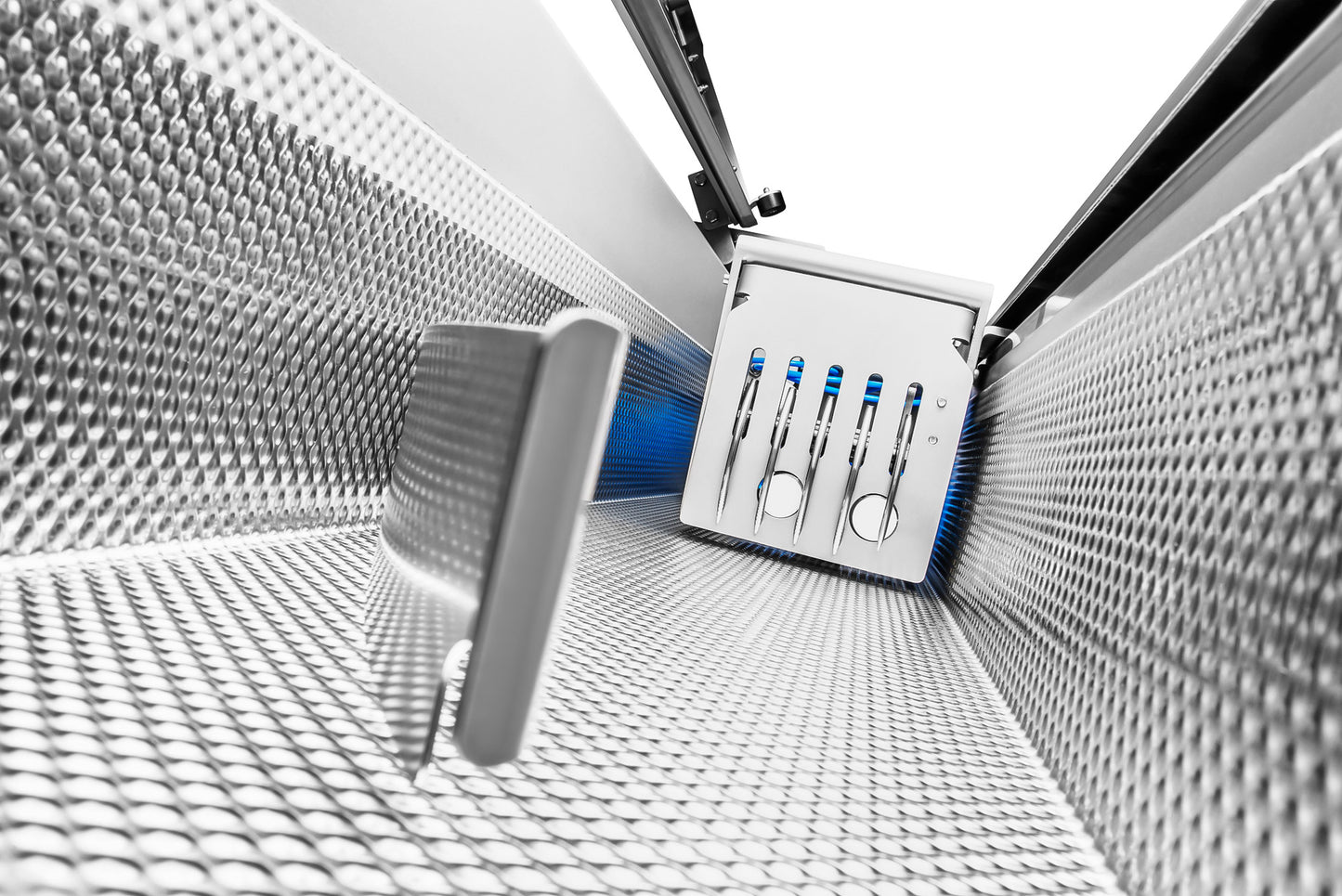

- Precise result also for on the bone products due to MHS micro-toothed blade

- Adjustment of blade speed

- Exact feed due to less friction on structural surfaces

- Forward feed mode selectable, continuous or step by step

Optional Features

- This software takes over one additional step of the operation. As soon as you put the product to be sliced into the machine and close the flap, the cutting process will start automatically.

- Automatic distribution of the remaining slice

- Automatic flap starts after closing the flap

- Pneumatic gripper

- Automatic ejector for remaining slice

- Optimum hold due to adjustable gripper

Specifications

| Model | Model IC 700/36 ES Horizontal Slicer with Outfeed Conveyor |

|---|---|

| Chamber length | 27 inches |

| Chamber Width | 14 inches |

| Chamber Height | 14 inches |

| Product Thickness | .5 to 700 mm |

| Slices per minute adjustable | 120-300 with single blade |

| Programs | 100 |

| Motor | 8 HP |

| Voltage | 230 /460 V/ 60 HZ / 3 PH |

| Overall Dimensions | 78" x48" x58" |

| Weight | 1280 lbs |

Couldn't load pickup availability

Materials

Materials

Dimensions

Dimensions

Shipping & Returns

Shipping & Returns

-

Industry's Best Customer Service

Call our friendly and knowledgeable team to make sure you're getting the right item for the job. Our team has decades of food processing experience and is looking forward to hearing from you! 951-734-8152 or email us at support@rameqpt.com

-

Fast Shipping

We stock many of our items at our main facility in Corona, CA. Other items are ship form our 14 Strategically located distribution centers nationwide and internationally. Equipment is usually made to order and lead times vary. Contact us today for current equipment lead times. 951-734-8152.