Talsa

Talsa Model K30s Suprem Bowl Cutter

Talsa Model K30s Suprem Bowl Cutter

Advantages at a glance

- Very high cutting speed, fully variable from 500 up to 3500 rpm.

- Smooth start of knives due to electronic drives, overload protection.

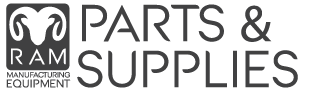

- German BE-Maschinenmesser knives, special high resistance KUT steel. Minimum space between all knives and the bowl thanks to its large central diameter.

- Simplified knife shaft, very reliable, with advanced quality bearings and seals for high revs, 2 years guaranteed.

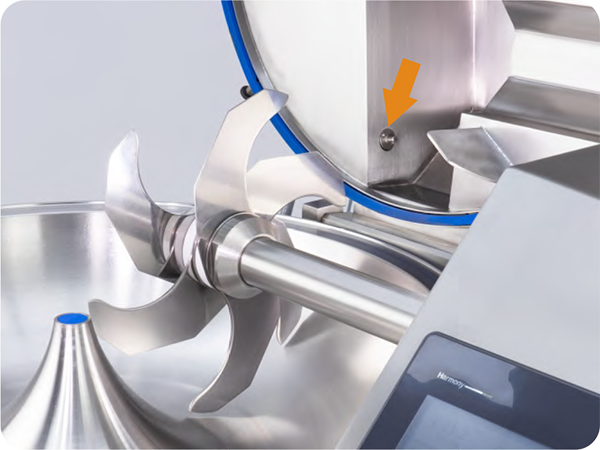

- Strong, all stainless steel construction, solid bowl and lid.

- Electric device to prevent condensations inside the machine frame.

- Adjustable, non-slip and vibration absorbing stainless steel machine feet.

- Excellent professional results with meat, vegetables, vegan/ vegetarian food.

The Talsa Model K30neo Bowl Cutter is designed for the production of all kinds of sausage hash. From small to medium slaughterhouses and industrial meat processors. The Talsa Model K30neo Bowl Cutter or bowl chopper is also suitable for a wide range of poultry, fish, pastry or vegetarian products, processed cheese and many commodities in the food processing industry.

The Talsa Model K30neo Bowl Cutter / chopper cuts, mixes and emulsifies all types of food products. From thick or very fine textures. It is simple to use, has an automated control system and is cleaned and maintained with ease.

The industrial bowl cutters and industrial bowl choppers are the same machine but carry a couple of different names. Some people still call the bowl cutters, buffalo choppers or buffalo cutters so it just depends on where in the country you come from.

The most common names are industrial or commercial bowl cutter or bowl choppers.

The industrial bowl cutter is one of the most versatile machines at a butcher shop or food processor out of all the machines in the facility.

Bowl choppers can be used to chop vegetables to make salsa’s. From liquid type salsa to chunky pico di gallo salsa. We have used bowl choppers to chop up garbanzo beans into humus, or dates into a date paste.

Commercial bowl cutters are best known in making sausage. There are several types of sausage depending on what part of the world the recipe comes from.

You can use the Talsa Model K30 Bowl Cutter to make Italian sausage which is a more chunky type of sausage. For this type of sausage you would run the cutting blades at a slower RPM and the bowl at a faster RPM.

If you were using your Talsa Model K30neo Bowl Cutter to make a more emulsified product like bologna, liverwurst or traditional hot dog, you would turn the bowl speed of your bowl chopper to a lower RPM and increase the speed of the cutter blades. At the very end of this type of process, the operator adds ice flakes to cool down the product and create that creamy texture of the meat.

We have made walnut butter, fresh masa, chopped garlic and flavored cream cheese just to name a few other products that can be processed by a Talsa Model K30neo Bowl Cutter or industrial bowl chopper.

RAM Manufacturing Equipment is located in Corona, California. We offer training, installation, service and parts for all the machines we sell. Including the Talsa Model K30neo Bowl Cutter and many others.

Call, E-mail or visit us today for more information!

Software and external connections

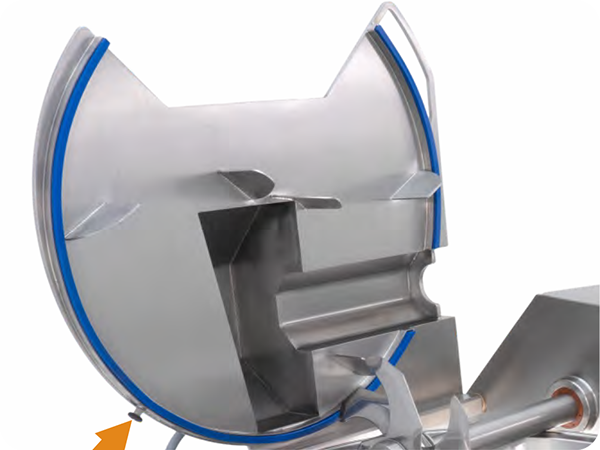

NEW: 10″ Digital Touch Display & TalsaControl 4.0

- Control panel with large 10” Schneider Electric digital touch screen, all information displayed simultaneously: knife speed, temperature, elapsed time and current time..

- 4 speed preselection buttons for knife speed, freely configurable.

- Very advanced and practical software with automatic stop options, triggered by temperature limit and/or elapsed time. Intuitive, easy to use.

- Interactive recipes, can be stored and executed directly on the machine’s screen.

- Talsa EcoCut Power Control to determine the machine power required to achieve the desired cutting results at any time of the process.

- Industry 4.0 digital solutions for maintenance, process integration and custom solutions.

- Remote Service and Support access over secure internet connection. (router/ethernet or mobile phone)

951-734-8152

info@ramaxwell.com

Technical data

| Technical specifications | K15s | K30s | |

| Bowl capacity | 15 liters (4 Gallon) | 30 liters (8 Gallon) | |

| Approximate batch size | soft mix tough mix |

± 4-12 kg (± 9-26 lbs) ± 4-8 kg (± 9-18 lbs) |

± 5-22 kg (± 11-48 lbs) ± 5-15 kg (±11-33 lbs) |

| Machine power | 2.3 kW / 3 HP | 5.6 kW / 7.5 HP | |

| Electric power type | single-phase | three-phase | |

| Max. consumption | 220/230 V 380/400 V |

8.7 A – |

22.9 A 13.2 |

| Knife speed | variable preselect-buttons |

500 to 3500 rpm freely configurable |

|

| Linear knife speed | 9-37 m/s | 12-48 m/s | |

| Net weight approx. | ± 165 kg (± 364 lbs) | ± 330 kg (± 728 lbs) | |

| Sound pressure level at 1 m | ± 68 dB(A) | ± 71 dB(A) | |

| Operating temperature | +5º to +40º C (40º to 105º F) | ||

| Recommended relative humidity level | 20 to 90 % | ||

Couldn't load pickup availability

Materials

Materials

Dimensions

Dimensions

Shipping & Returns

Shipping & Returns

-

Industry's Best Customer Service

Call our friendly and knowledgeable team to make sure you're getting the right item for the job. Our team has decades of food processing experience and is looking forward to hearing from you! 951-734-8152 or email us at support@rameqpt.com

-

Fast Shipping

We stock many of our items at our main facility in Corona, CA. Other items are ship form our 14 Strategically located distribution centers nationwide and internationally. Equipment is usually made to order and lead times vary. Contact us today for current equipment lead times. 951-734-8152.