Thompson Meat Machinery

Thompson Meat Machinery Model 900E Ergonomic Meat Mixer Grinder

Thompson Meat Machinery Model 900E Ergonomic Meat Mixer Grinder

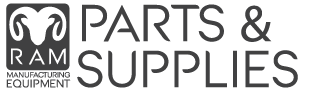

The Thompson Meat Machinery Model 900E Ergonomic Meat Mixer Grinder is designed with a conical bowl and mixing ribbon. This design offers many benefits in ergonomic operation like increased production and efficiency. This machine has been designed and developed to the high standards of safety and finish demanded by CE / USDA and GS regulations

The Thompson Meat Machinery Model 900E Ergonomic Meat Mixer Grinder has the ergonomic characteristics of low loading and high discharge heights making it easier for the operator to load lugs into the mixing bowl without spillage. The primary objective of the Thompson Meat Machinery Model 900E Ergonomic Meat Mixer Grinder is to eliminate the strenuous work practice of bending over the mincer discharge which is known to cause strain and discomfort to the operator.

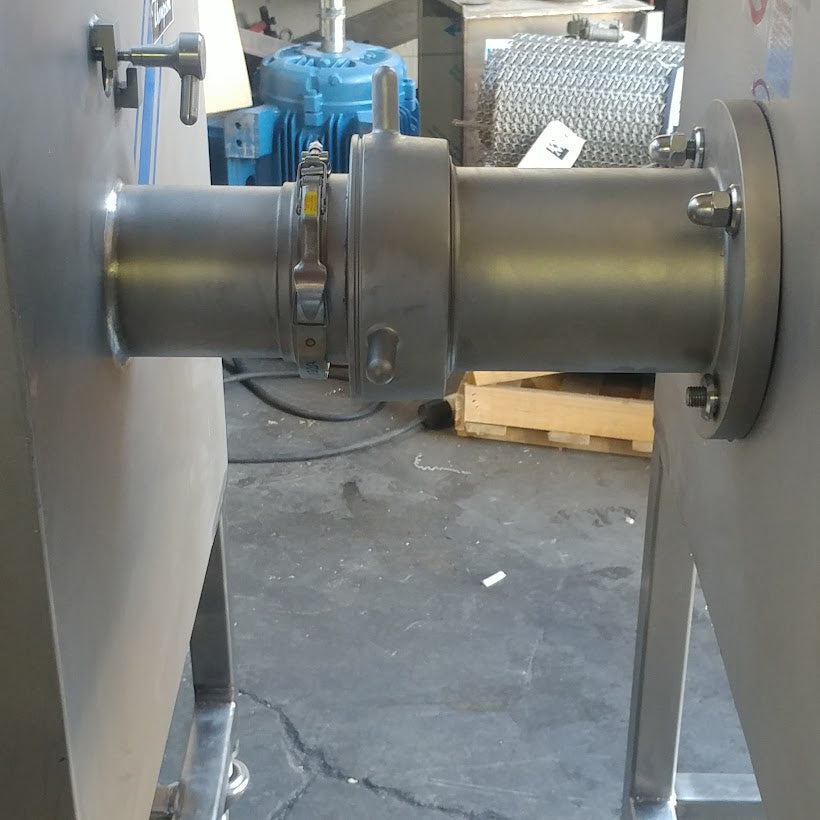

The Thompson Meat Machinery Model 900E Ergonomic Meat Mixer Grinders design is not just user friendly but it is innovative as well. The feed screw operates at a right angle to the bowl offering unique advantages. This feature guarantees almost zero temperature increase during the mixer/ grinding process, extends shelf-life, improves product bloom and enhances the overall presentation.

Because its unique design the Thompson Meat Machinery Model 900E Ergonomic Meat Mixer Grinder achieves outstanding output. The Thompson Meat Machinery Model 900E Ergonomic Meat Mixer Grinder’s modern, compact and functional design is space a perfect addition for demanding meat processing operations.

RAM Manufacturing Equipment is located in Corona, California. We offer training, installation, service and parts for all the machines we sell. Including the Thompson Meat Machinery Model 900E Ergonomic Meat Mixer Grinder and many others.

Call, E-mail or visit us today for more information!

235 Benjamin Dr. Suite 102

Corona, CA 92879

951-734-8152

admin@ramaxwell.com

The Thompson Meat Machinery Model 900E Ergonomic Meat Mixer Grinder has the ergonomic characteristics of low loading and high discharge heights making it easier for the operator to load lugs into the mixing bowl without spillage. The primary objective of the Thompson Meat Machinery Model 900E Ergonomic Meat Mixer Grinder is to eliminate the strenuous work practice of bending over the mincer discharge which is known to cause strain and discomfort to the operator.

The Thompson Meat Machinery Model 900E Ergonomic Meat Mixer Grinders design is not just user friendly but it is innovative as well. The feed screw operates at a right angle to the bowl offering unique advantages. This feature guarantees almost zero temperature increase during the mixer/ grinding process, extends shelf-life, improves product bloom and enhances the overall presentation.

Because its unique design the Thompson Meat Machinery Model 900E Ergonomic Meat Mixer Grinder achieves outstanding output. The Thompson Meat Machinery Model 900E Ergonomic Meat Mixer Grinder’s modern, compact and functional design is space a perfect addition for demanding meat processing operations.

RAM Manufacturing Equipment is located in Corona, California. We offer training, installation, service and parts for all the machines we sell. Including the Thompson Meat Machinery Model 900E Ergonomic Meat Mixer Grinder and many others.

Call, E-mail or visit us today for more information!

235 Benjamin Dr. Suite 102

Corona, CA 92879

951-734-8152

admin@ramaxwell.com

Regular price

$0.00 USD

Regular price

Sale price

$0.00 USD

Unit price

per

Shipping calculated at checkout.

Couldn't load pickup availability

Materials

Materials

Dimensions

Dimensions

Shipping & Returns

Shipping & Returns

-

Industry's Best Customer Service

Call our friendly and knowledgeable team to make sure you're getting the right item for the job. Our team has decades of food processing experience and is looking forward to hearing from you! 951-734-8152 or email us at support@rameqpt.com

-

Fast Shipping

We stock many of our items at our main facility in Corona, CA. Other items are ship form our 14 Strategically located distribution centers nationwide and internationally. Equipment is usually made to order and lead times vary. Contact us today for current equipment lead times. 951-734-8152.